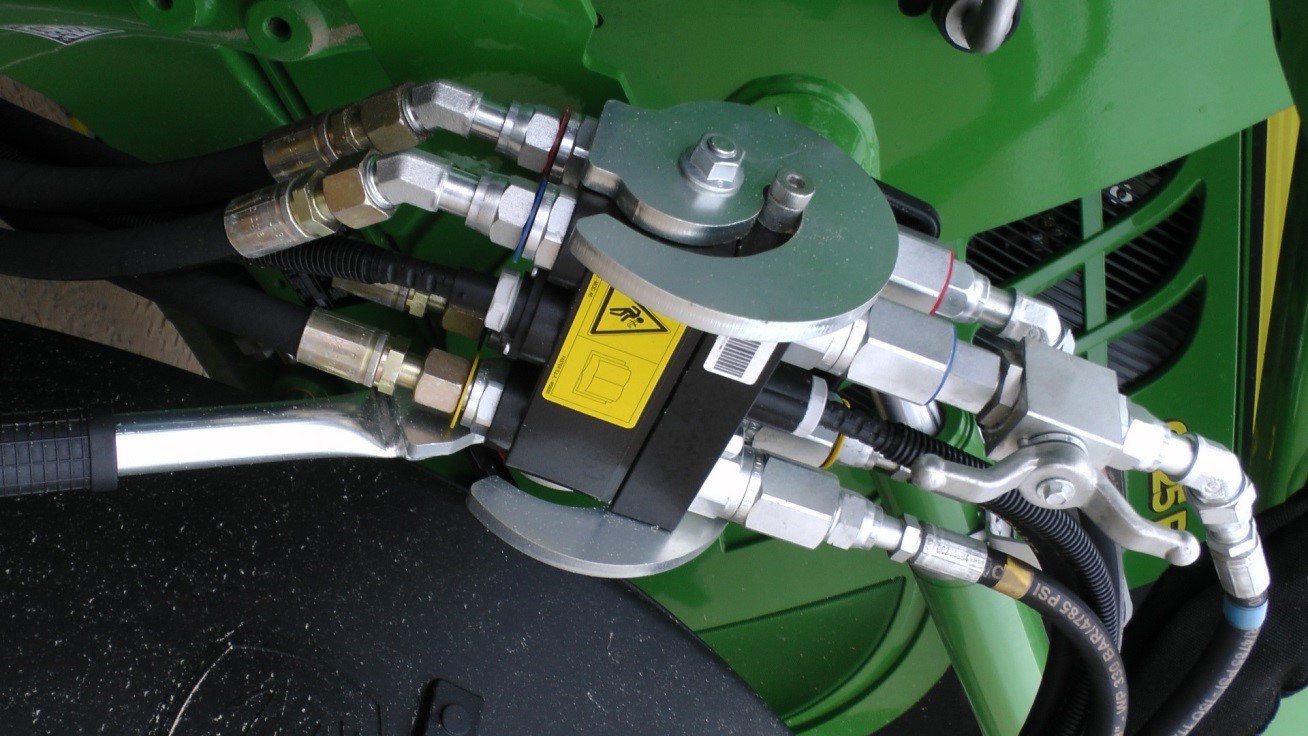

Honing is the precision machining process in which a very fine surface on a workpiece is produced using an abrasive tool. High quality honing of hydraulic cylinders is essential, as the effective operation of the pistons depends on the cylinder having a very fine surface finish, which can also prevent premature wear of moving components. Honing also creates a secure seal around a hydraulic cylinder, providing extended life and preventing costly leaks.

Everything You Need To Know About Honing Hydraulic Cylinders

Topics: CNC Honing

A 2019 Highlight: Hone All Secures BAE Systems – Air Approval

Many of us take a mental inventory of the year just gone as we count down the minutes to the New Year, and at Hone All we are lucky to have had numerous favourite moments to choose from last year.

Topics: News, Aerospace Industry

Join Us At The Make UK 2020 National Manufacturing Conference

We are very much looking forward to our first major event of 2020 – the Make UK National Manufacturing Conference on 25th February.

Make UK: The Manufacturer’s Organisation, is the country’s leading professional group for manufacturers and their supply chain partners. The National Conference brings together thought leaders, policymakers and industry representatives for a day of seminars, networking opportunities, talks and training events.Topics: Exhibitions

Shortly before Christmas, we were delighted to be awarded the Best Sub Contract Machining Award, as part of SME News Magazine’s 2019 Energy & Power Awards.

Topics: Deep Hole Boring, News, Aerospace Industry

Investing in new equipment is always an exciting and busy process. As part of our planned expansion and improvement plan in 2020, we are delighted to announce the arrival of our next Pinacho 3 metre CNC lathe, which is scheduled to arrive in our workshop within the next few weeks.

Topics: Aerospace Industry, CNC Lathe

A 2019 Highlight: Hone All - Forward Ladies Award Nominee 2019!

For individuals and businesses campaigning for greater female representation in the engineering and manufacturing sectors, the Forward Ladies (FL) National Awards & Summit, held at the end of November 2019, was an extremely positive event. The National Awards Grand Final, held in a prestigious event at the Royal Armouries in Leeds, was the culmination of several FL regional contests that took part earlier in the year, with finalists from each being submitted to the grand final.

Topics: News

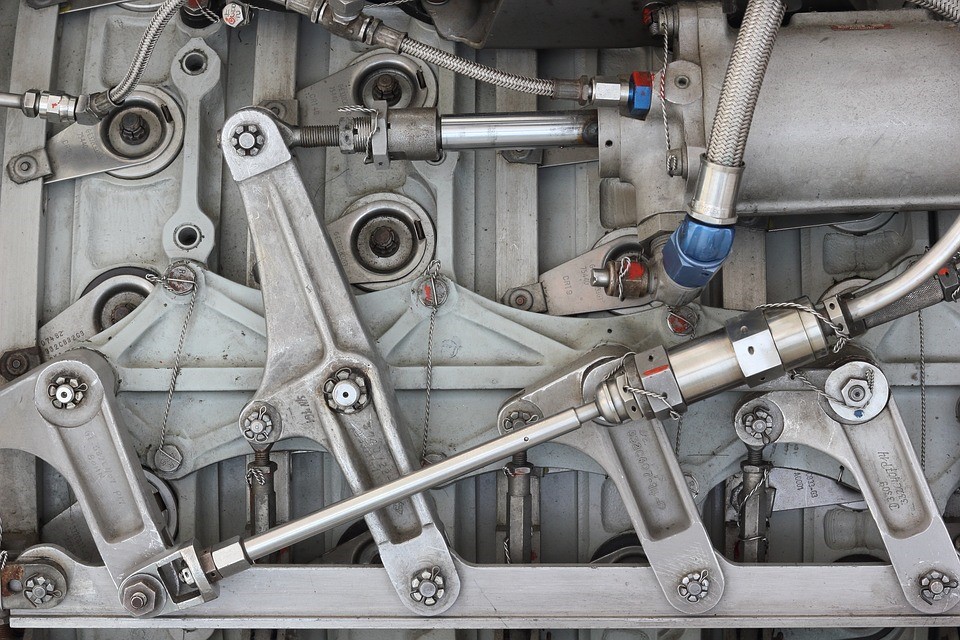

How To Ensure Quality For All Components In An Aerospace Project

The aerospace market experiences scrutiny like few others. Financial accountability is coupled with moral accountability, and brands can be extinguished with minor errors. All parts of an aerospace project, therefore, require the highest levels of quality. Here’s how to ensure that every component can fly safely.

Topics: Aerospace Industry, Precision Engineering

4 Metals Used In Aeroplane Manufacture And Why They Are Used

In aerospace manufacturing, the choice of metal makes a big difference. This is because different metals behave differently when under stress, when heated, and when cooled. The characteristics of metals have a strong influence on manufacturing techniques, such as deep hole boring and gundrilling. Here’s a quick guide.

Topics: Aerospace Industry, Precision Engineering

Why ‘Quality Over Cost’ Is So Important In Precision Engineering

Cost or quality? Or both? Everyone grapples with this conundrum. However, dodgy parts are at the root of many engineering failures. From biomedical equipment to oil and gas components, there are multiple scenarios where precision matters. Today, we look at the enduring problem of cost versus risk.

Topics: Precision Engineering

Why Is Effective Honing So Important For Hydraulics?

Machine honing is a precision metalwork technique used to create super-flat, shaped, and super-smooth surfaces. By applying an abrasive stone anvil to cut against the metalwork, and applying intense pressure and movement, pieces of any shape and size can be altered to exact material specifications.

Topics: CNC Honing, Precision Engineering