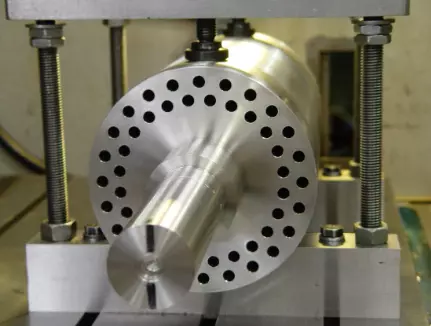

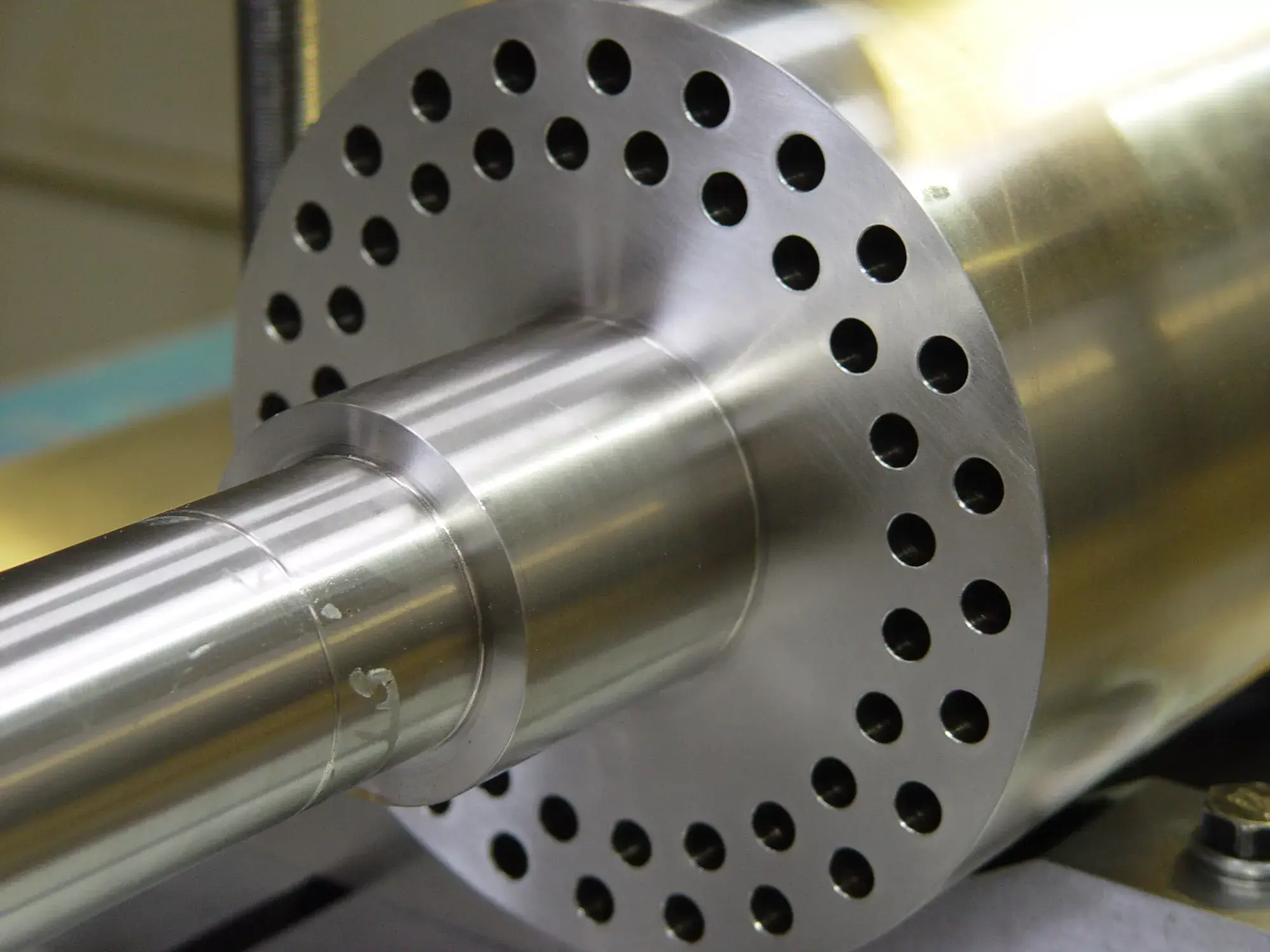

When the limitations of conventional drilling pose an obstacle to your project, CNC gundrilling provides a cost-effective and reliable way to drill holes with a diameter to depth ratio in excess of 100:1. CNC gundrilling combines Computer Numerical Control (CNC) technology with high-quality, carbide gundrill tools to create holes between 3mm and 28mm in diameter, up to 2,500mm deep.

WHAT YOU SHOULD KNOW BEFORE YOU ASK FOR A CNC GUNDRILLING QUOTE

Topics: CNC Machining Quotes

Drilling 101: The 5 Main Drilling Technologies Explained

Drilling is, in simple terms, the process of creating a hole in materials using a variety of drilling tools to vary the size or depth of the hole. In precision engineering, however, drilling is more complex, yet it’s a common and important process that uses advanced, specialist machinery to deliver outstanding accuracy and speed. The type of equipment best suited to drilling depends on several factors, so it’s vital to select the right technology for the job. Here is an outline of the five main drilling technologies, the majority of which we can provide here at Hone-All.

Topics: Deep Hole Drilling, Deep Hole Boring, Gundrilling, Trepanning

How To Avoid Deep Hole Drilling Mistakes When Working With Steel, Aluminium, And Titanium

Effective deep hole drilling demands precision to achieve close tolerances and an optimum surface finish, both of which are negatively affected by incorrect speeds or feeds. Drilling vibration, or chatter, can occur for a variety of reasons, including poor machine preparation, incorrectly chosen cutting tools, improper speeds, and sometimes cause excessive run-out.

Topics: Deep Hole Drilling, Deep Hole Boring

What You Need To Know Before Requesting A Sub-Contract Quote

Requesting a quotation is the first step when you decide to outsource your precision manufacturing to Hone-All, or indeed any another provider. However, to be able to provide you with an accurate cost prediction for your project, your trusted supply partner will require the following information:

Topics: CNC Machining Quotes

5 Common CNC Drilling Mistakes and How to Prevent Them

5 Advantages of Using Bespoke CNC Machined Parts

Bespoke CNC machine parts have wide applicability in manufacturing and bring a range of important benefits, which we’ll discuss in this article. Modern precision engineering uses computer-aided design (CAD) software and computer numerical controlled (CNC) machining equipment to create high quality components to demanding specifications, with accurate repeatability over any volume.

Topics: CNC Machining Quotes, CNC Machining

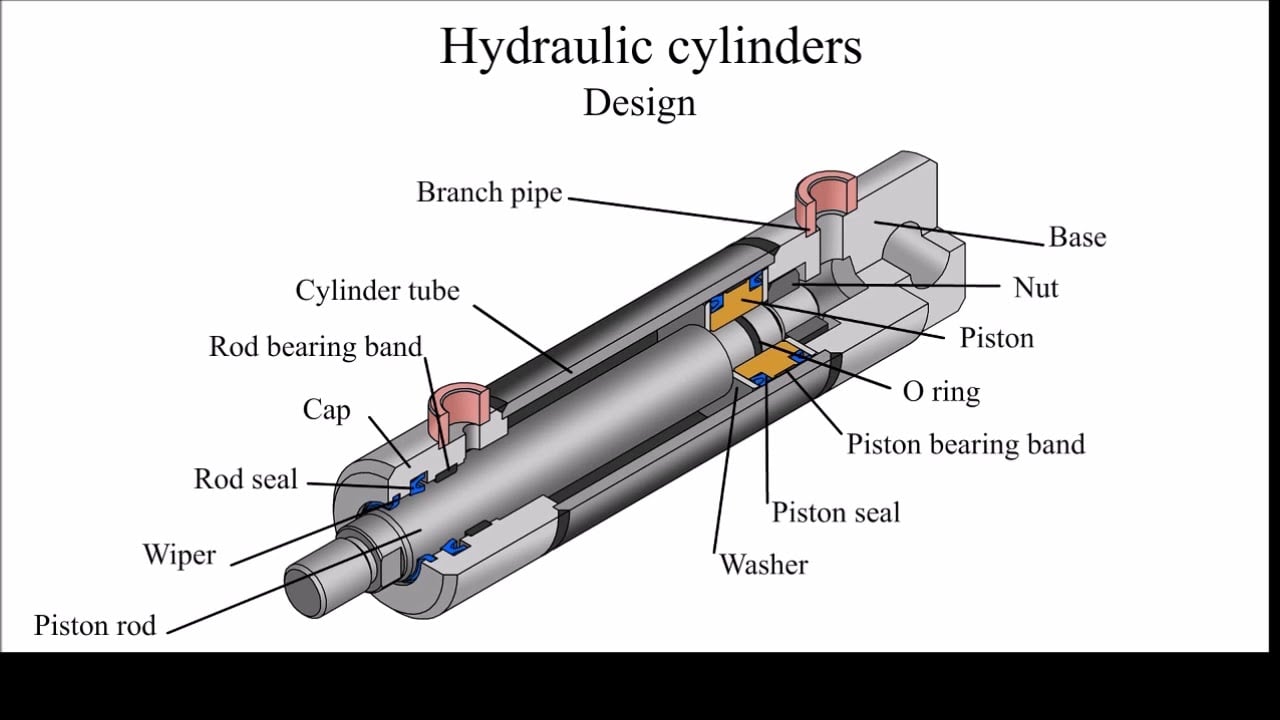

A hydraulic system failure is always inconvenient and costly but, in some industries, it can put users at serious risk of injury or death. Aircrafts, for example, rely on hydraulics to move critical mechanisms, including the landing gear, brakes, and wing flaps, so any system failure could result in catastrophic consequences.

Topics: manufacturing, Hydraulic Systems, #ukmanufacturing

Topics: CNC Machining, CNC Deep Hole Gundrilling, CNC, CNC Gundrilling

Boosting Efficiency: 4 Ways Advanced CNC Gundrilling Techniques Reduce Costs

Topics: Gundrilling, UK Manufacturing, CNC Deep Hole Gundrilling

How Production Control Software Could Boost UK Manufacturing

The adoption of modern production control software applications, such as RedAnt, has profound implications for efficiency and productivity among SME manufacturers, and could significantly boost UK manufacturing output over the next few years.

Topics: manufacturing, UK Manufacturing, #ukmanufacturing