At Hone-All we are committed to the belief that simpler is better when it comes to supply chains. Most people know Hone All for our practical services in advanced honing, boring, and CNC machining. However, we’re also dedicated to trouble shooting, project management, and ironing out supply chain creases.

Honing The Supply Chain: How You Can Say No To Costly Delays!

Topics: Deep Hole Drilling, Deep Hole Boring, CNC Honing

Understanding CNC Honing: 6 Factors That Influence Your Results

Topics: CNC Honing, UK Manufacturing, CNC

4 Advantages Of CNC Deep Hole Gundrilling For Enhancing Production Quality

Topics: CNC Deep Hole Gundrilling

Topics: Trepanning

Dealing With Wall Thickness During Deep Hole Boring

Tubular components are found in many sectors of manufacturing and industry, but their design and specification varies enormously according to their intended application. In some sectors, such as aerospace and medical instrumentation, for example, tubes must be machined to incredibly tight tolerances to achieve exceptional performance and lightness.

Topics: Deep Hole Boring

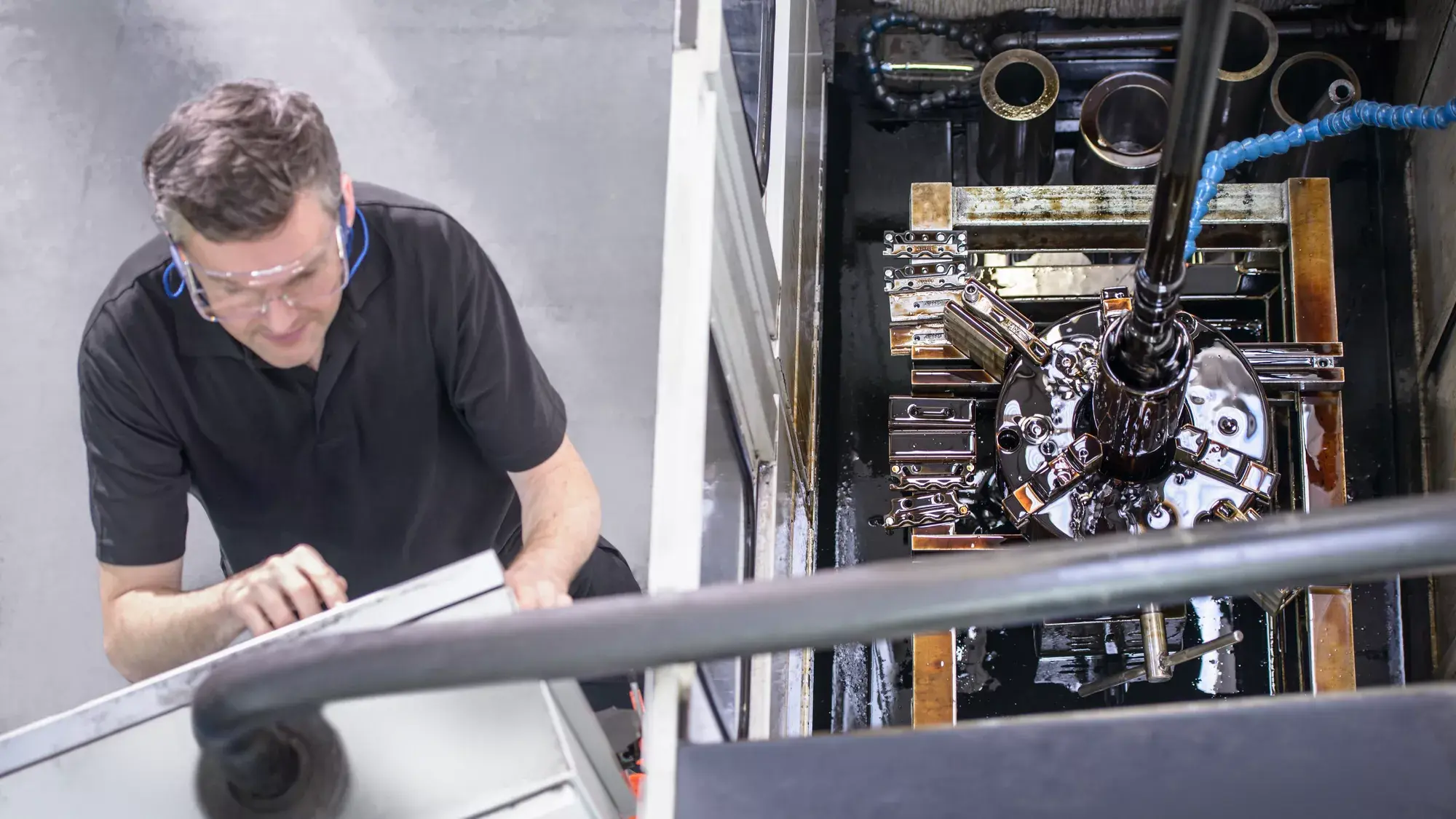

There are several reasons why you may choose to outsource your drilling and boring work to a specialist company such as Hone-All. It may be that your business doesn’t possess the specialist equipment necessary to complete tasks precisely or quickly enough to meet expected lead times. Alternatively, you may be swamped with orders and don’t have the capacity to fulfil all competing demands at one time. Or, perhaps, you recognise the benefits of trusting a team of drilling and boring specialists to deliver the high standards within your timescale, to help to cement your business’s positive reputation with your customers.

Topics: Deep Hole Drilling, CNC Turning

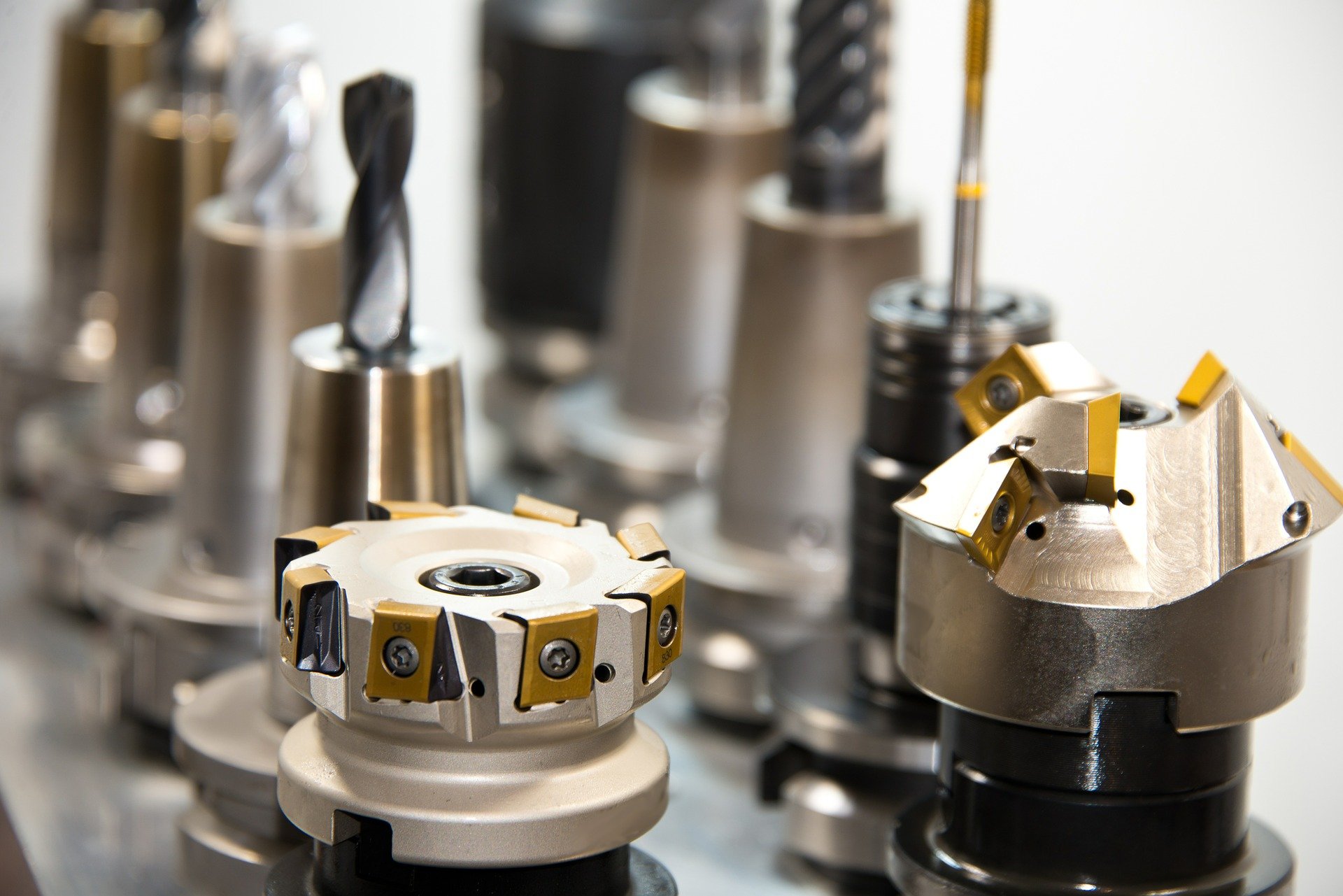

Drilling is one of the most important processes in manufacturing, enabling holes of different shapes and sizes to be made in a variety of materials. However, drilling machines vary considerably, as they are designed to carry out different jobs, so it’s essential to understand which type is most suited to your production needs.

Topics: Trepanning

5 Essential Benefits Of CNC Honing For Precision Manufacturing

Topics: CNC Honing, UK Manufacturing

How CNC Honing Enhances Hydraulic Cylinder Performance

Topics: CNC Honing, #shoutaboutukmfg, #supportukmfg

Topics: CNC Honing, #shoutaboutukmfg, #supportukmfg, #ukmanufacturing