You may think that they all say that, and they probably do.

Therefore, it’s worth taking two or three minutes to understand our justification for claiming that you will not find better – or at least understand our approach and the way we do business. It’s the only way for us, and it has delighted thousands of customers throughout the years. We believe we have the winning formula of professionalism, advanced technology and industry expertise and it’s all at your disposal.

How Confusion Easily Creeps In To A Quote

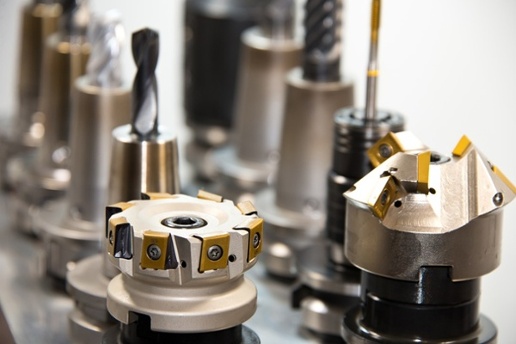

The technical complexity of the specialist services available at Hone-All, including deep hole boring, deep hole drilling and honing, are unsurprisingly something of a mystery to some people. That’s perfectly understandable unless you have worked within a specialist machine shop and put in the hours learning about and perfecting these techniques.

This sometimes makes it difficult for customers who want to utilise these services. The variations of the different levels of machining available can dramatically impact the costs quoted at the initial stage but understanding the implications of those differences is not always intuitive from a brochure or website. There can be a whole host of factors that may at first appear to be just complications and cause for confusion. They can lead to a cost V quality conflict from simply specifying the level of machining, the technical specification and the overall impact on the finished component.

That is why we never just key some numbers into a spreadsheet and take the first answer it pops up.

Every Single Job Deserves Thorough Investigation

Issuing quotes on request is simply a cost of doing business but it’s a considerable cost to us. This is because genuine lasting quality starts with a true and perfect understanding of the requirement. We study drawings and almost always follow up with a series of questions. Our desire to gain clarity and certainty is your guarantee that you will get what you want – not just from us but from the whole process and resulting product.

We have often seen quotes being returned quicker and at a cheaper rate than ours. If we are able to speak to the customer and explain why our costings may be a little higher than our competitors, in most cases it is because we have included additional operations after considering the overall finished quality of the component and how the results of our machining will impact our customers machining further down the production sequence.

We appreciate that for some people the cost is everything and the only consideration. We don’t go along with that because going with the lowest initial cost can come back to bite one all too often.

Aerospace Industry Standards EN 9100 For Your Benefit

Regardless of your industry sector, all our procedures and order processing adhere to this superior standard. Not all suppliers apply this strict Aerospace Industry standard to all their orders unless it is specifically required, whereas we follow EN 9100 procedures for all components irrespective of sector or specification. This effectively eliminates the risk of product defects causing you problems down the line.

A Case In Point

For deep hole boring on bores from 20mm – 200mm+ diameter, a standard industry tolerance quoted would be ± 0,25mm. Therefore, any tolerances lower than these parameters will most likely result in a need for honing. However, adding honing to the cost of the sub-contract machining can often result in our quotation not being as cost-effective as the prices offered elsewhere. The choice here is, do we simply quote our standard tolerance and guarantee to win the work with the lowest price, or do we quote on a basis that will ensure the quality the customer really requires? If the tolerance isn’t achieved, the first approach avoids an unwelcome surprise additional cost or delay to the promised lead time when we are half way through the order. The same applies to surface finishes.

At Hone-All, we always choose to err on the side of caution as quality must be paramount and the costs and lead time known in full at the start of the project.

Quality Or Price: Do You Have To Choose?

Quality versus price does not have to be a compromise. At Hone-All we find that the solution comes through honest and open communication. We are transparent about our work and will be upfront about your likely project costs. This being said, our goal is to help you achieve the maximum possible value within your budget. So, based on an assessment of your needs, we will suggest solutions that come in at the lowest achievable cost, bearing in mind your quality requirements and delivery schedule.

Find Out More

You have nothing to lose by calling us today on 0845 5555 111 for a brief informal chat about your specific requirements. We are always delighted to take on new challenges that exercise our team’s ingenuity and innovative skills. Alternatively, use this easy form to request a quote. International visitors may call us on +44 1525 370666 or please e-mail us at sales@hone-all.co.uk