It's common for companies to use third party accountants, solicitors, and IT providers when they don't have teams of experts in-house. However, in recent years, manufacturing companies have realised that they can also benefit from working closely with precision engineering firms to handle parts of their manufacturing process. What advantages could your business gain from using Hone-All's subcontract machining services?

1) High-Quality Results

Honing is a key process in the manufacture of parts for a wide range of components. However, it's one that relatively few manufacturing businesses have the plant and expertise to carry out in-house to the required standards. Honing is rarely taught on engineering courses, so it could be difficult for your company to find employees with the appropriate skills to carry out the work – and it may be something that is only needed occasionally during production, making it not cost-effective to invest in the relevant machinery and training.

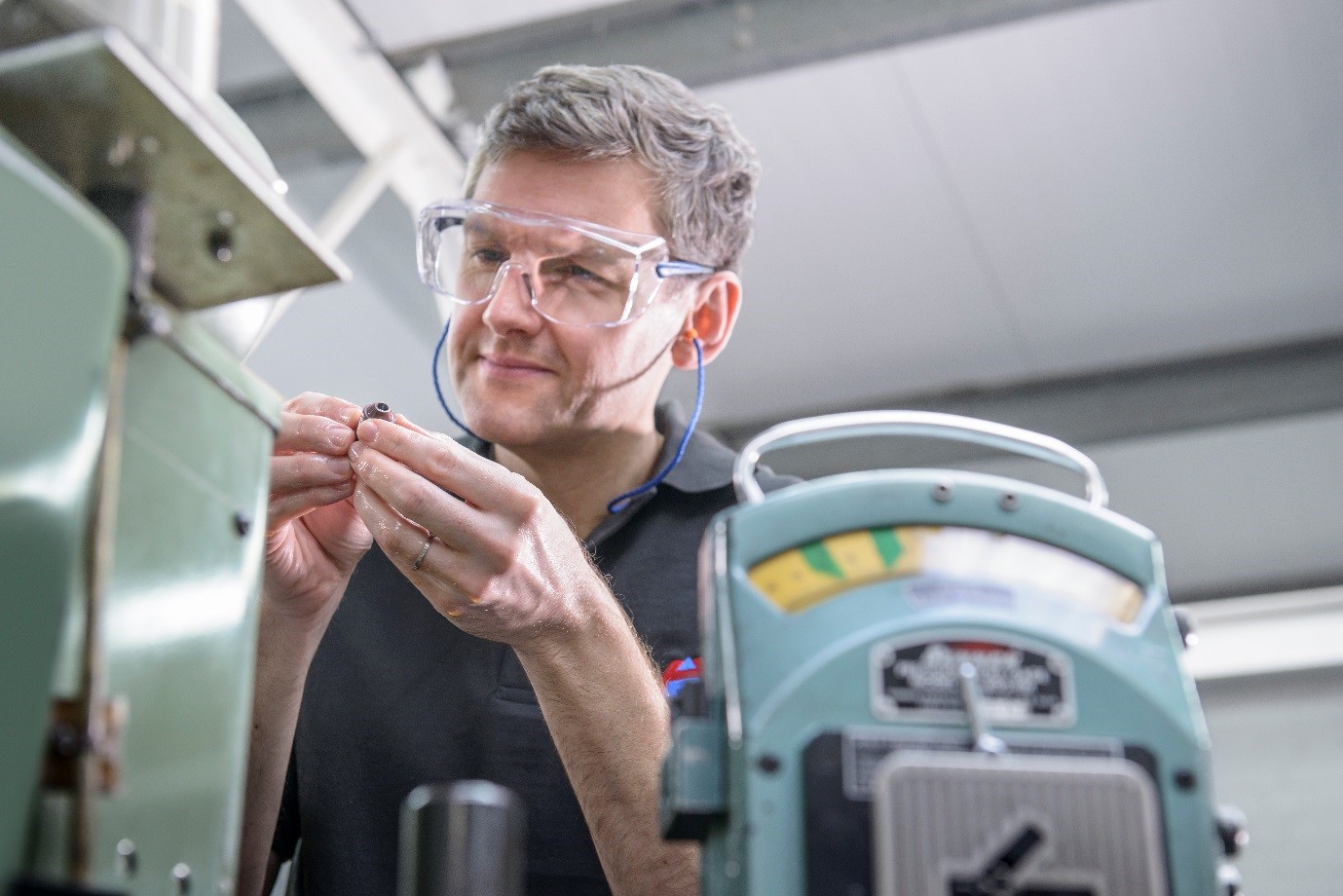

While we now offer a host of precision engineering services, we began as a specialised honing company and the process still lies at the heart of our operations. Our engineers are highly trained, and we've invested heavily in research and development, designing our own honing tools and machines over the years. As a result, we can deliver exceptional results, even when handling the most challenging of projects.

2) Lower Overheads

Honing machines and tools are expensive and can take up a substantial amount of floor space. They also need to be operated by skilled engineers. Therefore, opting to carry out your honing work in house could be a costly affair. What's more, you may find that your machinery can't complete all of the tasks that you need it to or that it soon becomes obsolete (CNC controls and automation systems are developing rapidly at the moment).

We have state-of-the-art honing equipment on site, including modern computer numerical control (CNC) honing machinery, which allows us to remove more stock without sacrificing the finish quality. We've also completed bespoke projects for many leading manufacturers in the aerospace, medical equipment, and motorsport sectors, so we are experienced in providing cost-effective solutions for complex tasks that standard honing machines are unable to perform.

When you use Hone-All, you won't need to worry about the costs involved in hiring and training specialist engineers to carry out your honing, as you'll have an entire team of specialists to hand.

3) Increased Productivity

If you don't have the right employees, machines, or tools to carry out precision honing to tight deadlines, the efficiency of your production line will suffer. Outsourcing your honing work to Hone-All will enable you to streamline your operations effectively and boost your company's productivity.

By choosing to work with a UK-based company, you'll also have peace of mind from knowing that your operations won't be impacted by international shipping delays. This will enable you to reduce lead times, improve customer satisfaction and maximise your profits.

Find Out More

To learn more about our honing and CNC honing services, please complete our contact form, to speak with one of our engineers.