Manufacturing enterprises within the UK's engineering sector continue to be significant contributors to the economy. Just over one-eighth of the 5.5 million registered enterprises in the UK are in the engineering sector. And yet, in comparison, there are only a handful of companies providing specialist services, and even fewer who carry out all those specialist services in-house.

Specialist Honing Services – A Major Contributor To The Manufacturing Sector

Topics: Deep Hole Drilling, Deep Hole Boring, CNC Turning

Drilling deep holes is not simply a matter of using a longer drill.

As hole depth increases, the process becomes far more difficult to control and requires specialist equipment to achieve consistent results. Heat builds quickly, tools are more prone to deflection, and swarf removal becomes increasingly challenging. Without careful control, it is easy for bore straightness, surface finish, and dimensional accuracy to suffer.

Topics: Deep Hole Drilling, UK Manufacturing

Hone-All - Not Your Average Gun Drilling or Boring Machine Shop

You may think that they all say that, and they probably do.

Therefore, it’s worth taking two or three minutes to understand our justification for claiming that you will not find better – or at least understand our approach and the way we do business. It’s the only way for us, and it has delighted thousands of customers throughout the years. We believe we have the winning formula of professionalism, advanced technology and industry expertise and it’s all at your disposal.

Topics: Deep Hole Drilling, Deep Hole Boring, CNC Honing, Gundrilling

What You Need To Provide For A Deep Hole Boring Quote

Deep hole boring is a machining process in which holes are drilled with a depth to diameter ratio in excess of 100:1. The process is used to create bores in a range of materials, from aermet to aluminium to superalloys, and has applications in a variety of industries, including:

Topics: Deep Hole Boring

At Hone All, we combine the latest cutting-edge deep hole drilling technology with superior technical knowledge to provide precise machining solutions. Our gundrilling services offer an accurate, cost-effective solution for businesses, matched by rapid response times.

Topics: Deep Hole Boring, Gundrilling, Precision Machining

If there is one thing that we all want to be sure about when heading into a hospital environment, it is that we are stepping into a world of precision equipment. A review of medical literature shows that even routine procedures are fraught with difficulty. For instance, a typical lumbar puncture has five primary areas of risk, and that is before the quality of the tube begins to even enter the equation. As doctors explain: “what we need to achieve is difficult enough without equipment also being a factor”.

Topics: Tube Manufacturing

Key Reasons To Choose Trepanning Over Solid Core Drilling

If you’re planning an engineering project in which you’ll need to drill holes into metals, it’s essential to choose the most suitable method of drilling to achieve the optimum results. Drilling and trepanning are two options, but it’s vital to understand the difference, and the advantages, to make an informed decision.

Topics: Trepanning

How To Save Money On Deep Hole Drilling, Boring & Honing

Tubular based components are used in tens of thousands of applications by manufacturers in a wide range of sectors. These components vary enormously in size, capacity and use, but the method by which each is made is broadly similar.

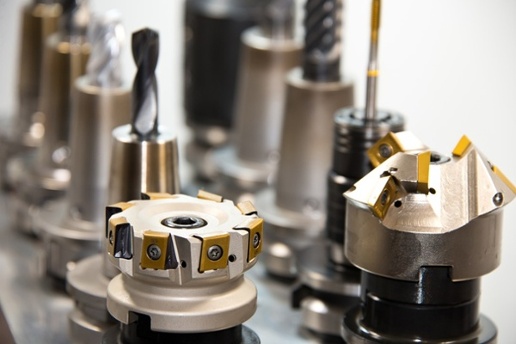

The precision engineering methods used to make industrial tubes and shafts include deep hole drilling, deep hole boring, gun drilling, CNC turning and CNC honing.

Topics: Deep Hole Drilling, Deep Hole Boring, Save Money

CNC honing is an excellent way to achieve tighter tolerances and better surface finishes on a wide range of precision machined components with a round bore. Here's a simple guide to this sophisticated process.

Topics: CNC Honing

Does A Lack Of Advanced Digital Technology Harm UK Manufacturing?

Despite the plethora of digital processes in the modern economy, recent research indicates that 96% of UK manufacturers feel there has been an underinvestment in digitisation in their sector.

The survey results span a diverse range of areas, from aerospace and defence to medical instruments and electronics, but the sentiments were consistent. Survey respondents overwhelmingly felt that overreliance on legacy technologies was harming the UK's manufacturing industries' prospects.

Topics: manufacturing, supply chain, #supportukmfg, #ukmanufacturing