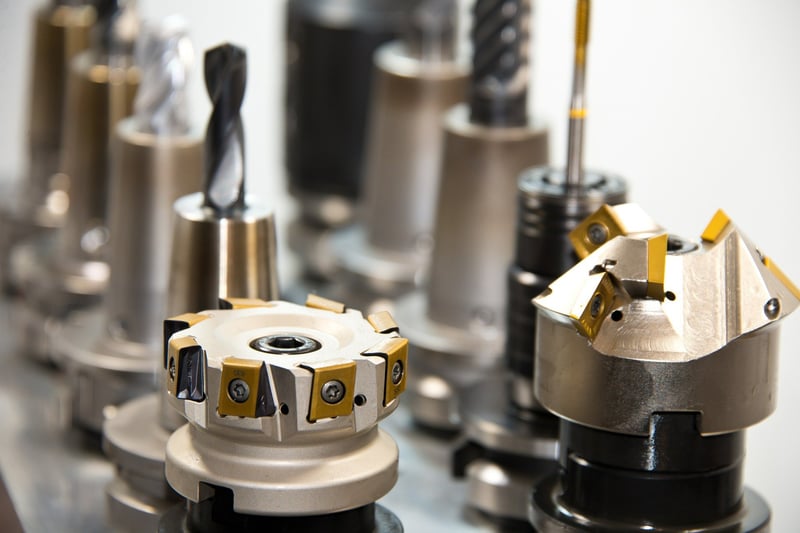

Drilling is one of the most important processes in manufacturing, enabling holes of different shapes and sizes to be made in a variety of materials. However, drilling machines vary considerably, as they are designed to carry out different jobs, so it’s essential to understand which type is most suited to your production needs.

At Hone-All, we deliver expert drilling using several types of manual and CNC drilling machines, providing your business with a reliable, highly accurate service upon which you can depend.

Our Drilling Services

By drawing on the latest technology with outstanding technical ability, at Hone-All we provide precision drilling for a range of industries including the petrochemical, aerospace, and hydraulic sectors, offering a cost-effective, responsive service that refuses to compromise on quality.

Deep Hole Boring

Deep hole boring is a process of creating long holes in solid bars and is one of our specialities at Hone-All. Specialist drill heads are expertly assembled with bearing pads, inner and outer tips and is then fitted into a high precision drill tube. With this tooling, we can create precision bores from 20mm and up to 203mm in diameter, using the latest machine tool technology to achieve superlative accuracy, close finishes, and excellent surface finishes.

Gundrilling / Deep Hole Drilling

In CNC gundrilling - sometimes referred to as deep hole drilling – the tool is a fluted tube with a carbide tip and is used to drill deep holes in metals at high depth-to-diameter ratios. Using a single cutting edge instead of a conventional twist drill, gundrilling removes chips from the substrate as it advances. Our range of gundrilling machines drill holes between 3mm and 28mm, to depths of 2500mm.

Trepanning

Unlike deep hole boring, trepanning only cuts away the outer edges of the hole when drilling, so that the central core of material can be collected from the hollow. By contrast, drilling destroys the material in the hole, turning it into chips or swarf.

Trepanning is a rapid operation that consumes less energy, even when boring into hard metals, and produces less waste. It is also ideal for boring diameters larger than 100mm or when high levels of accuracy are not required.

EDM Drilling

EDM drilling produces quick, highly accurate, small deep holes, making it the perfect solution for the rapid machining of conductive metals. EDM hole drilling utilises an energised rotating tube electrode with high-pressure flushing to achieve outstanding accuracy; if you have high volume applications and require a responsive service, ask about our EDM drilling.

Spark Erosion

Spark erosion, or Electro Discharge Machining, is an invaluable method for machining more complex or intricate shapes, using electrical discharges, or sparks. By using discharges between two electrodes that are separated by a dielectric liquid, material on the substrate can be carefully and precisely removed. During the process, electrical energy is converted to heat, which stimulates melting between the electrodes, allowing for the high standard of surface finish and the drilling of tiny holes.

Hone-All: For All Your Drilling Needs

At Hone-All, our experts can advise you which drilling method is most suited to your application, so for more information, get in touch on +44 1525 370666. Alternatively, click here to obtain a free quote, and we’ll be in touch promptly.

Image Source: Pixabay