Hydraulic cylinders underpin the operation of countless machines in a range of industries, from aerospace to construction and manufacturing to mining, and therefore must perform reliably under high pressures and demanding conditions.

The performance of a hydraulic cylinder heavily depends on the dimensional accuracy and surface quality of its internal bore: two critical parameters that CNC honing is uniquely equipped to optimise with precision and consistency.

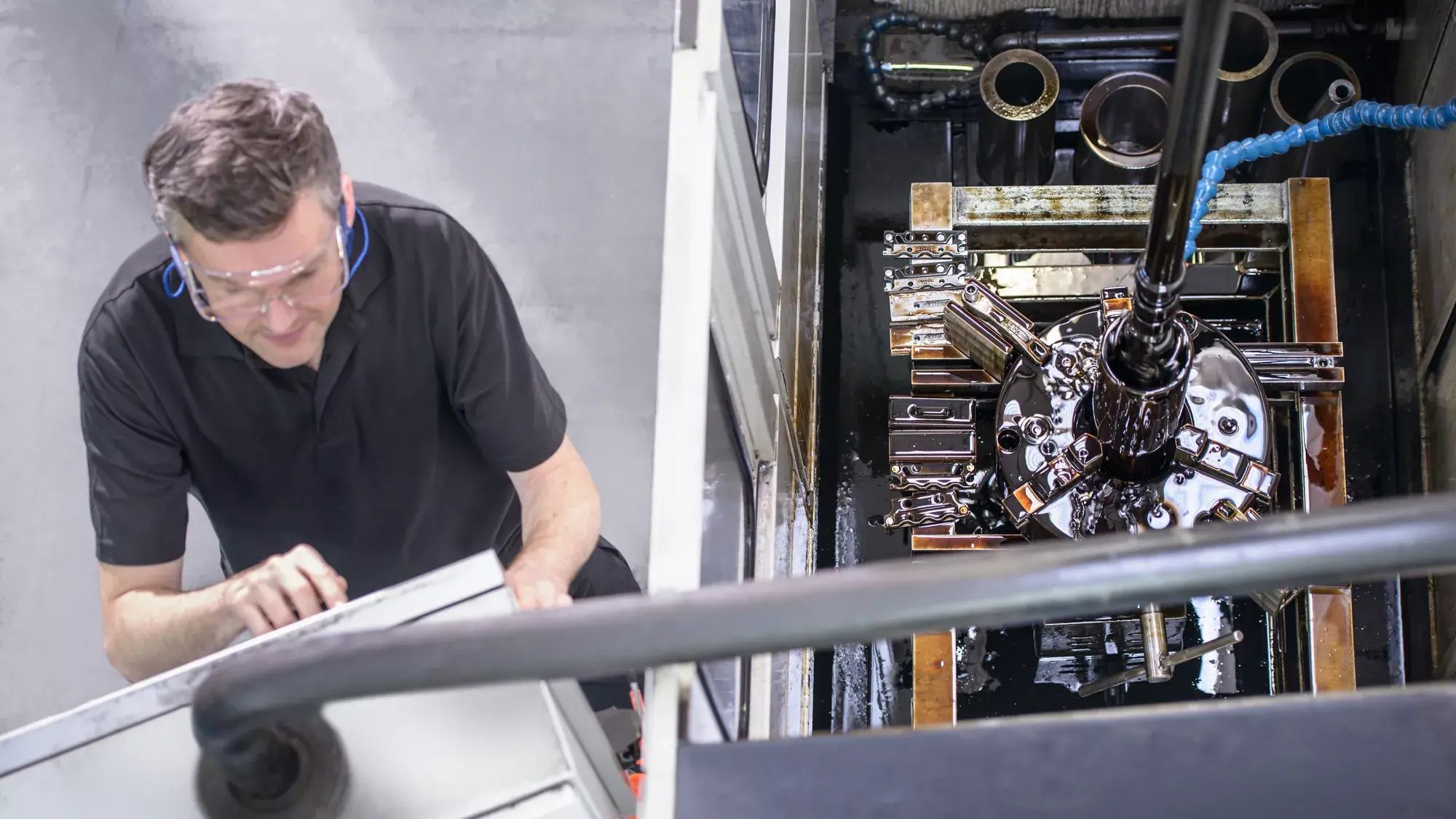

Unlike general machining processes, CNC honing is a precision finishing method which is used to refine internal cylindrical surfaces to tight tolerances and specific surface finishes. It enables consistent results with minimal material removal, making it ideal for hydraulic applications where surface finish, friction reduction, and seal integrity are essential.

Superior Surface Finish

For hydraulic applications, CNC honing is used to create a finely controlled cross hatch surface finish within the cylinder bore which promotes oil retention, reduces friction between the cylinder wall and piston seals, and ensures smoother operation. The quality of the surface finish directly impacts the efficiency of hydraulic motion, particularly in systems that require rapid, repeatable actuation.

Enhanced Seal Performance

Seal integrity is critical in hydraulic cylinders. An uneven or rough surface can compromise the seal, leading to internal leakage, reduced pressure retention, and operational inefficiency. CNC honing corrects microscopic imperfections and ensures a round and consistent bore, thereby providing an optimum surface for seals to effectively function, even at high pressures.

Improved Cylinder Efficiency

With lower internal friction and minimal leakage, honed cylinders offer more efficient fluid control. Systems run cooler and require less energy to achieve the same output, increasing overall system responsiveness. In high-cycle environments, this can deliver significant operational improvements and reduced wear on components, thereby reducing future downtime and repair or renewal costs.

Increased Component Longevity

By delivering both dimensional accuracy and optimal surface characteristics, CNC honing extends the lifespan of hydraulic cylinders. Smooth, uniform bores reduce abrasion on seals and pistons, cutting the frequency of maintenance and decreasing the risk of premature failure. In critical applications, this results in improved operational reliability and longer periods between maintenance.

Consistency At Scale

CNC honing ensures repeatable precision across production batches. Whether producing one-off components or thousands of the same piece, the process delivers the same tight tolerances and surface quality every time. This consistency is vital for OEMs and maintenance teams who need to work to exact specifications, and reduces the likelihood of waste and reworks.

Looking To Improve Your Hydraulic Cylinder Performance?

At Hone-All, we provide high-quality sub-contract honing services to manufacturers across the hydraulic, aerospace, and heavy equipment sectors. Our advanced CNC honing systems are supported by decades of experience and an unwavering commitment to quality in every aspect of our service.

To find out how our precision honing solutions can enhance the performance, reliability, and longevity of your components, or to request a free, no-obligation quotation, please get in touch with Hone-All today.