In the middle of a viral pandemic, you simply can't afford to waste time and energy by waiting too long. You can't run the risk of moving anything that might harbour or transport pathogens across tight borders and lockdown zones. It's also crucial to support your local manufacturers during lockdown - without orders to keep them going, many may have to scale back or shut down, once lockdown has finished for good.

Why Has COVID-19 Encouraged The Domestic Production Of Critical Machined Components?

Topics: Domestic Manufacturing

Why Using A Local CNC Turning Company Will Improve Productivity

Are you looking for ways to improve your productivity? Your choice of CNC Turning and machining specialist may have more of an influence than you realise. In a world of choice, here are some of the reasons that going local can make a difference.

Topics: CNC Turning

It’s hard to imagine a world without tubes. Through them, liquids and gasses flow, and energy moves. Tubular components have travelled to the depths of the Mariana trench, have touched the surface of Mars, and have delivered life-saving injections to billions of humans and animals.

Topics: Tube Manufacturing

Why We Need to Keep Seeking out Fresh Perspectives in Manufacturing

There is a great saying – if you always do what you always did, you’ll always get what you always got! It is a phrase we use often when those who are not technically qualified, or as experienced in machining, as others throw a wild or mad idea into the mix when brainstorming or problem solving.

What Is The Average Turnaround Time For Gundrilling?

Gundrilling is a specialised art, so there can be a lot of confusion about basic variables such as time, cost, and quality. This can create a headache for buyers, especially as clients – who arrive from a variety of demanding sectors, such as aerospace, defence, and automotive – need to know that the finished product will meet their specifications with absolute precision. Let’s take a look at gundrilling timings.

Topics: Gundrilling

Precision Roller Manufacturing Process - 6 Steps You Need To Know

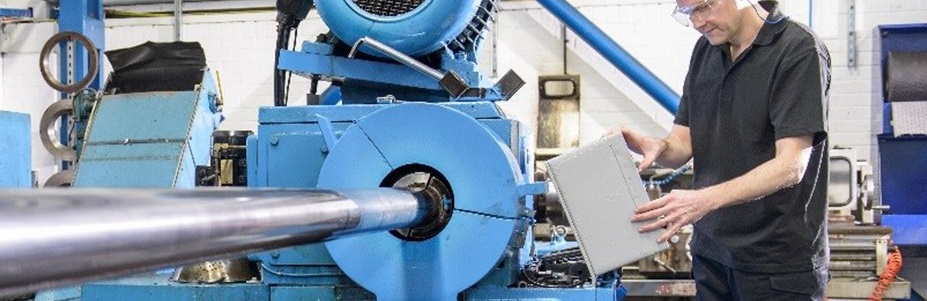

At Hone-All Precision, we specialise in precision rollers for a wide range of industrial applications. Our products are manufactured precisely to your design and machined for optimum efficiency and cost effectiveness. Whether you need 20 identical parts or a single, custom roller for a one-off project, our roller manufacturing process is geared up to provide the highest quality components available on the market.

Topics: Precision Rollers

A UNITED MANUFACTURING DIRECTORY FOR THE UNITED KINGDOM – WE NEED ONE BY 2021 AND HERE’S WHY!

The Corona virus crisis has highlighted how important it is for us all to work together - albeit at a distance. In British manufacturing, this has meant pooling our collective knowledge and resources across hundreds of miles and awkward, rolling restrictions on movement to create the best possible response to the biomedical engineering challenges created by the pandemic. Complex, vital machines, such as ventilators, brought together experts from sectors as varied as precision automotive engineering and clinically rated metal finishing in response the call to action from the Government and the need of the whole population.

Hi, I'm Gary and I’m a highly skilled CNC Turner and the longest serving machinist here at Hone-All.

Topics: CNC Turning

The Ventilator Challenge – Uniting Manufacturing, For Covid or Forever? An Interview with Garry Myatt, co-founder of UKMfgUnite

The 2020 pandemic has brought together some of the greatest minds from some of the most prestigious manufacturers in Britain to design, build, and ship vital medical equipment at very short notice.

Companies as diverse and skilled as Siemens, Rolls Royce, and BAE Systems have pooled their expertise to create large quantities of CPAP ventilators for use in hospitals and surgeries worldwide, in record time.

Topics: CNC Honing, oil and gas sector, Precision Machining, Precision Engineering

Hone-All Win Best Oil And Gas Sub-Contract Machining Service At The UK Enterprise Awards 2020

We are delighted to announce that we've won the 2020 UK Enterprise Award for excellence in Sub-Contracted Machining for Oil and Gas! We were extremely proud to be nominated by our customers for the Best Subcontractor Oil & Gas in the SME Energy & Power Awards at the end of last year and now we have been selected as the overall winner for Best Oil & Gas Subcontractor in the SME News Enterprise Awards 2020.

Although this is not to be formally announced until the end of August, we wanted to announce it as soon as possible to keep the positivity and good news flowing throughout our fabulous industry!

Topics: CNC Honing, oil and gas sector, Precision Machining, Precision Engineering