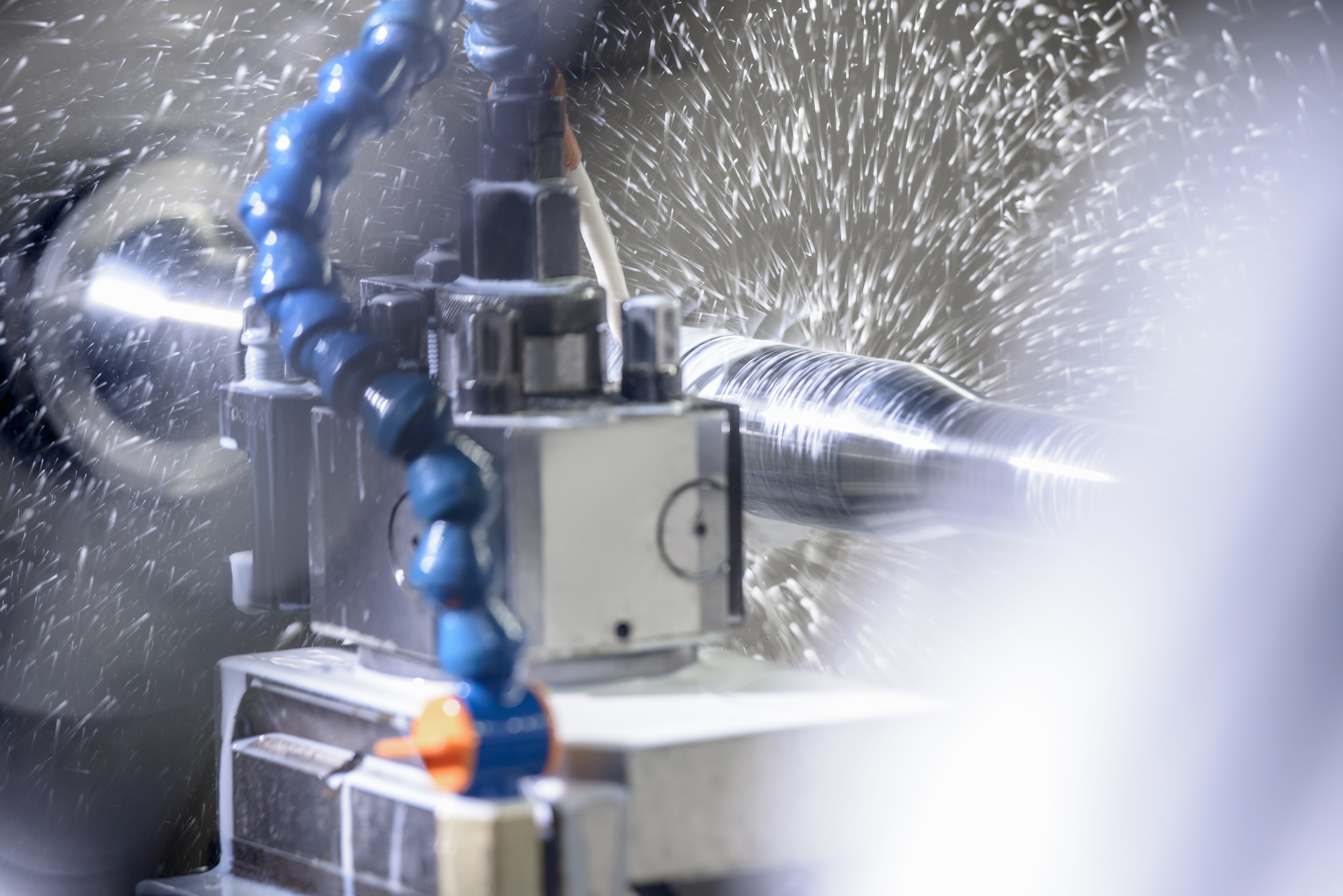

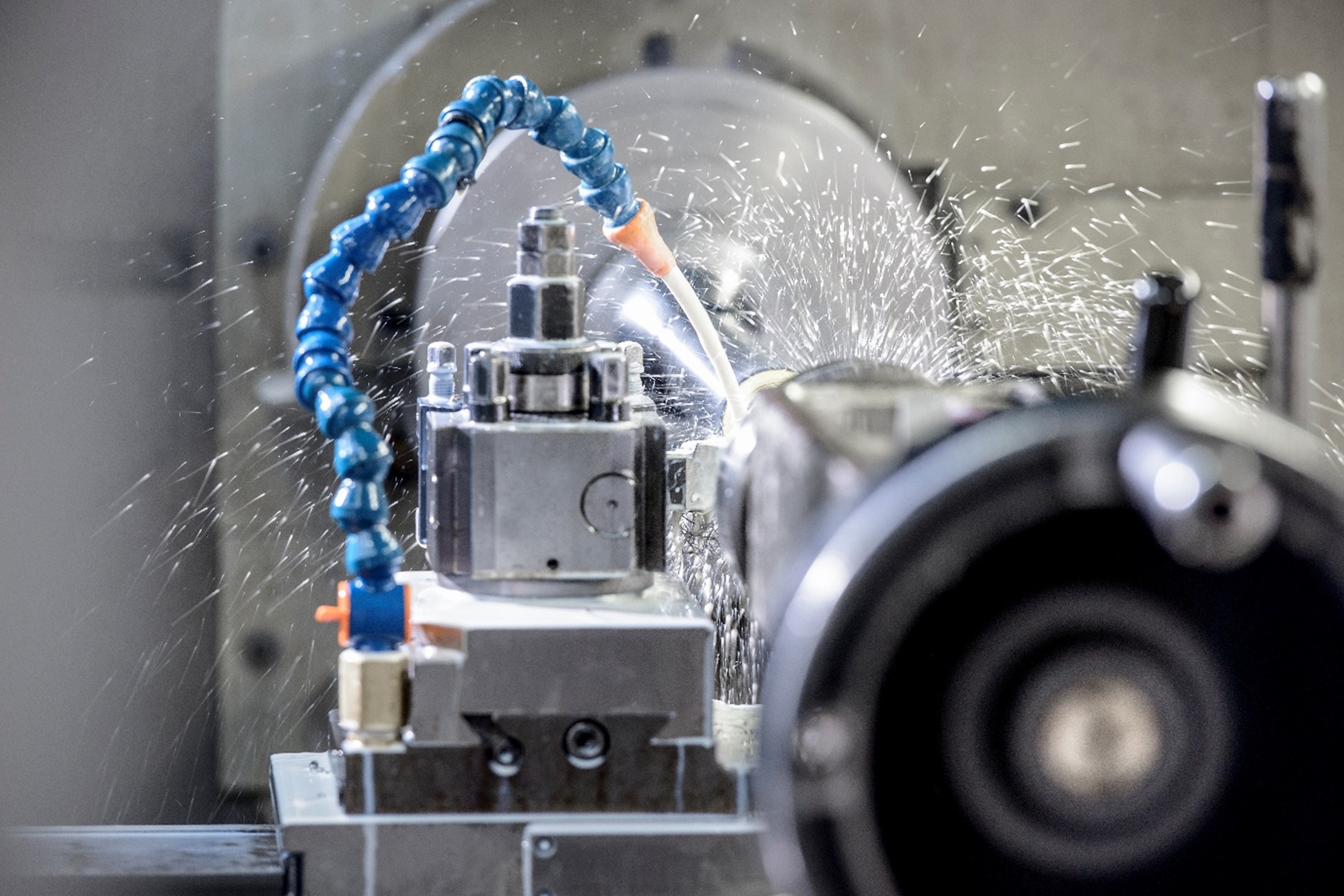

Computer Numerical Control (CNC) turning is a practical and efficient way of manufacturing custom components. However, while CNC lathes are capable of producing consistent results in a speedy and cost-effective manner, there are things that can go wrong with the process. Let's look at four of the most commonly experienced CNC turning problems and examine what can be done to resolve them:

4 Common CNC Turning Problems And Their Solutions

Topics: CNC Turning, CNC Lathe, CNC Machining Quotes

The impact of coronavirus on supply chains in 2020/21 has been immense. What started as a problem for China rapidly evolved into a global catastrophe, with supply chains experiencing considerable disruption due to trade restrictions and material shortages.

Topics: covid19, Domestic Manufacturing, 2021, manufacturing

What Does ‘Net Zero’ Mean For UK Manufacturers & The Green Recovery?

The UK has a legally binding target to reach ‘net zero’ carbon dioxide emissions by 2050. This bold target has already done much to affect the landscape of UK manufacturing, and is set to dominate the conversation over manufacturing strategies and technologies for the next 30 years. Reaching net zero, or carbon neutrality, necessitates reducing overall carbon emissions, and offsetting those emissions that can’t be avoided – e.g. by tree planting and other removal strategies. In order to reach the target, the UK will need to cut greenhouse gas emissions by 50% by 2030 – scarily that’s only 9 years away!

Topics: the green recovery, carbon emissions, net zero

Rishi Sunak’s Silver Lining – Take Advantage Of The Corporation Tax Super Deduction On Capital Investments From April 2021

The impending corporation tax hike from 19% to 25% for businesses reporting profits of £250K or more was one of the less welcome changes brought in by the 2021 budget and met with a mixed response from the business community. The changes come into effect from April 2023, with corporation tax being applied on a sliding scale, from 19% on small businesses filing £50,000 or less in annual profits to the full 25% on everything in excess of £250,000. Many businesses were critical of the move because, like many tax increases, the bulk of the burden is likely to fall on successful SMEs rather than large corporations, with the risk of the 6% hike deterring investment in growth at a time when it is sorely needed.

Learning The Lessons Of 2020 And Working Together To Build A Stronger Future

In a previous article, we speculated on trends that may play a greater role in the manufacturing industry throughout 2021 and beyond. These included a greater emphasis on workplace safety, increased adoption of automation and machine monitoring, and greater engagement with the Internet of Things in response to remote working and flexible shift patterns.

Topics: Insider, News, 2021, manufacturing

A Faster Route Out Of Lockdown? – How The New Flakt Group Air Treatment System Could Reduce Indoor Coronavirus Transmission

Encouraged by the success of the vaccination programme, businesses are looking forward to a safe and rapid transition away from lockdown and social distancing, back to normal working practices. However, even the most effective vaccination measures leave gaps through which vulnerable people may be infected, and although being vaccinated should stop you becoming ill, the extent to which it prevents you transmitting the virus to others is still unknown.

Topics: covid19, flakt group

What’s In Store For UK Manufacturing In 2021? 5 Trends To Look Out For

2020 was a year of great uncertainty for the UK’s manufacturing sector, but the year proved that the sector will prevail, with businesses becoming increasingly accustomed to finding workarounds to obstacles and prioritising collaboration over competition. So, in 2021, what will be the main manufacturing trends to look out for?

Competitor To Customer To Colleague! (Words From Uday, Our Newest Team Member)

I was so thrilled when Andrea contacted me and offered me the opportunity to join Hone-All.

Due to Hone-All being one of our valued suppliers as well as a competitor, I had visited previously and had been impressed with the processes and procedures on show. So much so, I did try and emulate and implement some in my previous company but didn’t really have the time to complete them before the decision was made to close us.

Topics: Insider, Job Opportunities, News

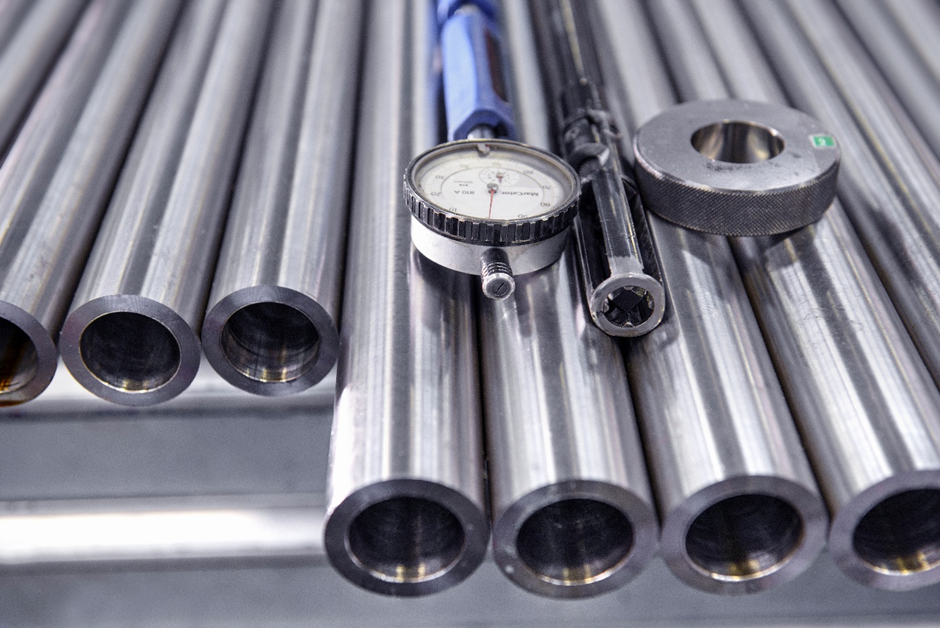

The Coffee Break Guide To Trepanning: Everything You Need To Know To Get Started

Trepanning is a specialist machining technique for drilling large holes in materials, particularly in situations where limited machine power is available, or if you wish to retain the core material from the bore instead of reducing it into swarf chips. Unlike conventional solid core drilling, trepanning only drills an annulus, or a ring, at the fringe of the hole, leaving the core intact so that it can be easily removed. Due to the lower amount of power required, since the core is not being drilled, the method is a suitable alternative if sufficient machine power cannot be attained. If you’re considering trepanning metal for your next engineering project, it’s worth considering the following key questions, to ensure that you plan every aspect to achieve the best possible results.

Topics: Trepanning, Precision Machining

In a post-COVID-19 world, the nature of global manufacturing supply chains will have to change substantially to be sustainable. Growing concerns about the environment, the role of the national economy in day-to-day life, and national unemployment also mean that businesses are beginning to shift their priorities when it comes to how they want to manage their production.

Topics: covid19