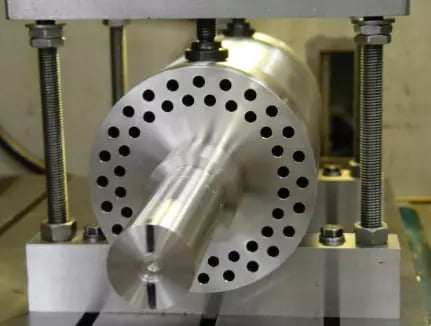

When the limitations of conventional drilling pose an obstacle to your project, CNC gundrilling provides a cost-effective and reliable way to drill holes with a diameter to depth ratio in excess of 100:1. CNC gundrilling combines Computer Numerical Control (CNC) technology with high-quality, carbide gundrill tools to create holes between 3mm and 28mm in diameter, up to 2,500mm deep.

Hone-All have a range of CNC gundrilling machines at our facility in Leighton Buzzard, which deliver highly accurate results in the shortest possible time. Ideal for straight drilled channels and precise round holes, our CNC gundrilling services can meet high tolerance parameters to ensure the greatest precision, with no need for time-consuming or expensive secondary finishing.

Industries We Serve

CNC gundrilling is suitable for a range of materials, including high grade alloys, stainless steels, aluminium, titanium, and thermoplastics. Industries we work with include:

- Injection Moulding

- Aerospace

- Medical technology

- Hydraulics

- Petrochemicals

- Motorsport

Information/Parameters We Need To Quote For Deep CNC Gundrilling

- The material specification – this is essential to ensure accurate quoting as material properties differ, as do the speeds and feeds required to machine them efficiently.

- Outside dimensions – we need this to assess which machine the component can be held on as well as to ensure we have a suitable wall thickness to ensure the drilling process can be completed safely.

- Inside diameter of the bores required – this is required to ensure we have tooling available, as although we have a vast range in stock, certain materials, such as Inconel, may require specialist tooling, as do blind bores with specific forms at the base.

- Overall length – as with the first two, these are required for tooling and machine capacity decisions and help us calculate the weight of the components.

- The bore type – i.e., is it a through bore or blind bore? If it is a blind bore, is a specific form required, such as a flat bottom or a particular radius at the base? Standard deep hole drilling leaves a sharp W shape at the bottom of the bore. Any non-standard form can increase unit cost due to the requirement for specific drill grinding or bespoke tooling requirements.

- Bore quantities and positional details – CNC gundrilling is most often utilised on parts which are not being drilled on centre, or holes, or multiples of holes, are required in fully machined blocks / milled sections. To quote accurately, we need the number of bores required, their position of them, and the positional tolerances required in relation to each other and the outside diameter.

- The bore tolerance – bore tolerance is a major factor when quoting the CNC gundrilling process. If the tolerance is below the industry standard of ±0,1mm, a honing process may be required.

- The depth tolerance – if you require a blind bore, we need to know the tolerance required on the bore depth. As long as there is excess material on the length and it is a round bar, we can “back-face” to achieve tighter tolerances on depths.

- Any surface finish requirement – in addition to the bore tolerance, this is needed to ascertain whether we have to add a honing operation.

- T.I.R. or Straightness requirements – we need to know these as even though we may be only carrying out an initial gundrilling or deep hole drilling operation, we need to ensure there is sufficient material to be machined down to correct any drill wander. Industry standard for drill wander is 1mm per 1 metre drilled.

Why Choose Hone-All For CNC Gundrilling?

At Hone-All, we offer quality-assured CNC gundrilling that is guaranteed to deliver the tolerances and accuracy you need for your next engineering project.

With decades of experience with a wide range of projects, we have the skills, knowledge, and tools to achieve exceptional results no matter how challenging the requirement. We value our partnerships with our customers and deliver a bespoke service that consistently meets their needs, on time and within the agreed budget.

To find out more about our CNC gundrilling services or to request a free, no-obligation quotation, please call us on 01525 370666 or send us a message.