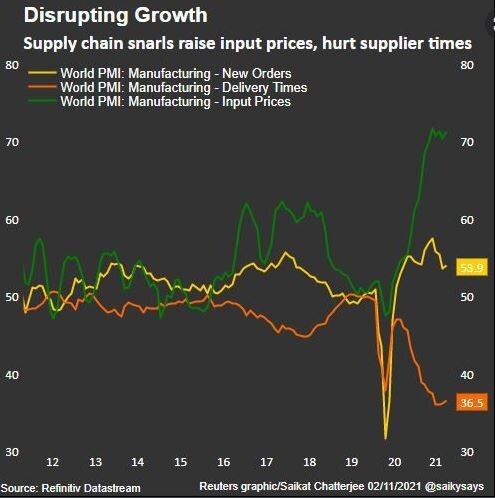

The pressure on global supply chains has been well-documented during the last three years, particularly as the Covid-19 pandemic took hold. But as the world begins to ease restrictions and normal life returns, businesses and consumers alike have observed how prices continue to be on the rise, driving up inflation and increasing the cost of living.

The price of many commodities have increased steadily since the middle of 2021, including many metals such as nickel, which recorded a huge price increase in early-2022. So, are rising commodity prices the result of ongoing supply chain problems or other factors that have emerged in recent months?

When There’s Simply Not Enough To Go Round

While there are several reasons why the price of metals are rising, the main driver is a shortage in feedstock.

Surging Global Demand For Raw Materials

Increasing demand for raw materials from the medical, hygiene, and food sectors in particular, has led to a global shortage, driving up prices. At the same time, manufacturers have been forced to maintain tight levels of inventory, in part due to sudden shutdowns as a result of Covid-19 restrictions and, in some regions, extreme weather, which is putting additional strain on supply chains and leading to shortages in key areas. The turbulent situation in Ukraine, coupled with global sanctions on Russia, is adding to pressures, with exports of metals, including titanium, nickel, iron ore, and mercury, plummeting rapidly.

The Uneven Terrain Of The Manufacturing Industry

Another key factor in the rising price of metals is the changing face of the manufacturing industry. Worldwide lockdowns led to many manufacturers closing, some on a permanent basis. As there was insufficient demand for their goods, particularly for those specialising in niche products who lacked the capacity or means to diversify, financial survival was impossible.

These supply chain gaps make it harder and more expensive for manufacturers to purchase valuable commodities.

An Upward Trend?

With materials becoming more difficult to find – particularly when price points are constantly changing – it’s likely that prices will continue to rise. Disrupted supply chains, particularly due to unstable political situations that could drag on for some time, are likely to persist, so manufacturers are going to need to find effective solutions to supply problems to futureproof their production lines without the costs spiralling beyond affordability.

Stay In Control Of Your Costs With Hone-All

If you’re seeking reliable ways to control costs and stay competitive, speak to Hone-All today.

Our precision engineering services are designed to deliver outstanding quality, giving you peace of mind that your machined components will be reliable and durable – just what is needed at a time of economic pressure.

Image Source: Unsplash