Selecting a good UK based CNC machining/precision engineering partner has important implications for the success of your project. If you make the right choice, then you will benefit from increased productivity, shorter project turnaround time, and lower production costs. Get it wrong, and you could be faced with delays, hidden costs, errors, and unforeseen complications.

Therefore, a lot rides on making the right choice.

Here are the five key factors you should consider when looking for the perfect CNC machining company for you.

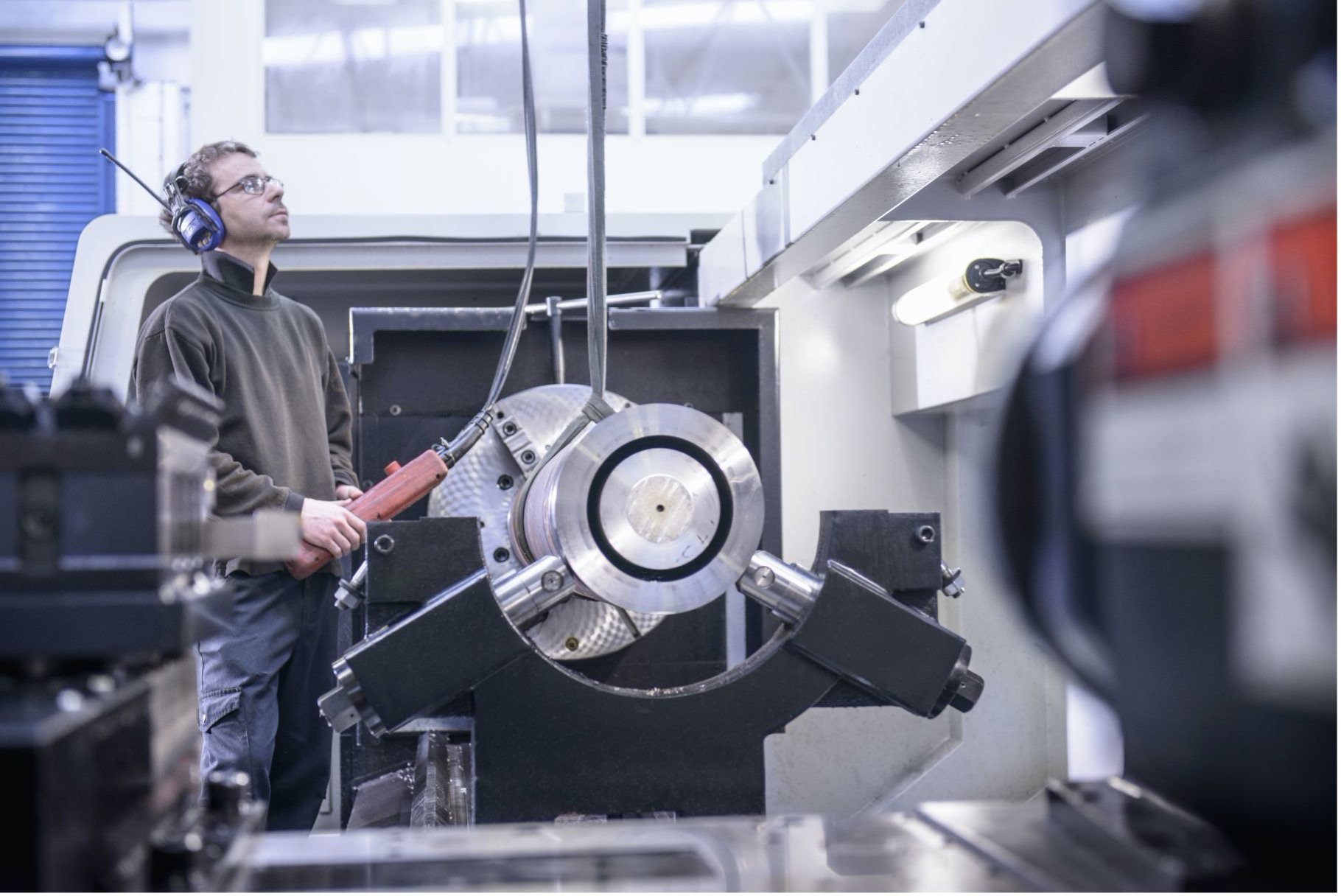

1) Assets and Equipment

Does the contractor have the physical equipment and tools to carry out your project successfully? Most leading machining companies have both CNC and manual equipment, giving them the flexibility to create a wide range of components, but some projects require specialist equipment or tooling, as well as the standard kit. It’s worth asking the company about the equipment they use, any investments in the pipeline, and the capacity for each machine. Many companies advertise this information on their website.

2) Technical Experience and Qualifications

As precision engineering has evolved, so have the skills needed to operate the latest equipment. How up-to-date is your contractor with the latest CNC equipment, software, and techniques? Companies that lean heavily on manual machining – e.g., those that specialise in small volumes or prototypes – may not be as skilled on CNC equipment even if they have the technology in house, or they may have to outsource some of the process. If they have to outsource, your risks of reliability and success increase further. Choose a contractor with the right mix of skills on their team to deliver your project on time and within budget.

3) Case Studies/Testimonials

The proof of the pudding is in the eating, and so it is with precision engineering. Happy customers are a sign that the contractor is doing something right, so ask to see both detailed case studies and informal reviews/testimonials from past customers in your sector, preferably referring to projects similar to yours. No company is perfect, so negative or neutral views can be illustrative too, especially if they demonstrate how the business deals with real-world problems in service delivery (delays, faults, staff issues etc).

4) Quality and Price

Quality is the most important factor, followed by price. High quality work costs money to produce and trained engineers deserve a fair wage, so at the very least you should raise a sceptical eyebrow at the lowest quotes – these businesses could be outsourcing their work to cheaper manufacturers in India or the Far East. On the other end of the scale, do your research to make sure that premium quotes accurately reflect the quality of the product (again referring to case studies, testimonials, and accreditations). What you want is excellent overall value based on a return on investment that suits your budget and production costs.

5) Location

While manufacturers have grown used to conducting business online in 2020/21 – to the extent that many clients and subcontractors have never physically met – location is still important for some projects. For large-scale consignments, you may want a local contractor that you can visit in person to oversee production, discuss queries, or inspect products, or to keep delivery costs low. For other projects this may be less important, but before you choose any contractor, we suggest reviewing their premises – whether in person or via a virtual tour – and becoming familiar with their key engineers and personnel. This builds relationships, instils confidence in their abilities and creates a personal connection between your two companies, making communication easier.

What Next?

Finding the right CNC machining service involves a delicate balance of quality, delivery times, expertise, and price.

To get the best value, work with the contractor, such as the great team here at Hone-All, who will make their first task that of understanding your specific needs and performance goals and provide you with a bespoke plan that fits your budget. You only need to check our Google reviews to see how we do this on a daily basis.

To find out more, or to discuss your requirements, please give us a call today.