One of the questions that often comes up is why Hone All invests in so many different types of deep hole drilling machines, tooling and equipment?

The reason is that requirements vary greatly within our sector and differing materials have unique personalities and characteristics.

Many would-be DIY drilling enthusiasts find that they end up with oversized bores, holes that run off excessively, or broken drills.

This isn’t because they are bad ‘engineers’, but because drilling relatively small diameter holes into metals can be tricky. Here are some ways in which the metal used affects the approach taken to deep hole drilling:

The Process

In deep hole drilling in metal the aim is to cut, rather than tear, the metal. When incorrect speeds or feeds are selected, chatter can occur adversely impacting the accuracy and surface finish of the bore being drilled. Avoiding chatter requires a careful balance of speed, clearance, and swarf extraction.

Metals have different properties that make them suited to different purposes. Some of them are easy to cut, and some – such as titanium – are prone to tearing.

However, differences between the properties within materials means that each metal is unique in terms of hardness, quenching behaviour, and tensile strength. Throw a gun-drilled hole into the mix, and you can have a match made in heaven or an ugly mess! It pays to get the set up correct.

Steel

Mild Steels are easier to machine than some alloy steels which are completely unrecognisable in terms of hardness and tensile strength. In terms of gun-drilling, the harder the material, the better it is as it is easier to control size and achieve a better surface finish in materials with a higher tensile strength.

The key is to always ensure that your feed and speed parameters are accurate and applicable to the tensile strength of the particular material you are machining.

Stable machine beds and support for the drill and component are also crucial to safely transfer any vibrations.

Aluminium

It’s often thought of as one of the easiest metals to work with. However, aluminium too comes in a wide variety of forms and each has its quirks.

Pure aluminium is soft, ductile and with a low density and low corrosion risk and this reason, aluminium is a popular choice for many applications. It is this softness that makes precision drilling of pure aluminium uniquely challenging.

Problems can occur if swarf becomes wrapped around the tool. Like long strings, these then block coolant flow which could result in a tool failure and result in a scrapped component.

Alternatively, just like steel, add a mix of alloys into aluminium and the tensile strength increases and machining is made easier.

Titanium

The medical industry is one area that is increasingly using titanium. This has raised some challenges for deep hole drilling - the metal is incredibly hard and has low thermal conductivity. It is also very prone to tearing, rather than drilling.

This means that anyone attempting to machine titanium needs to be an expert in feed and speed ratios. Tools also need to be precise and strong, and – even with generous coolant – used at slow speeds to reduce the build-up of heat.

Titanium also likes to be machined in a steady and formulaic way, and quality can be ruined by feed interruptions.

Closing Thoughts

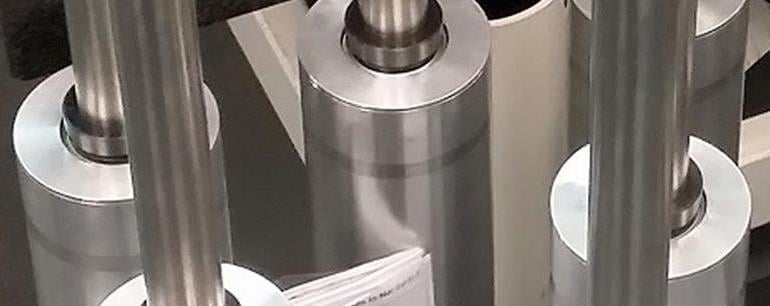

Anyone who works in deep hole drilling, boring, honing, or CNC machining needs to have a deep understanding of different metals and how to get the best out of them. When we shape, cut, and drill metals, it also helps to have the best machines. This is why we always invest in the latest precision machinery – so we can handle a wide range of projects for our customers at exacting tolerances. If you want to learn more, we’ve got a free guide, or you can call us on 0845 5555 111.