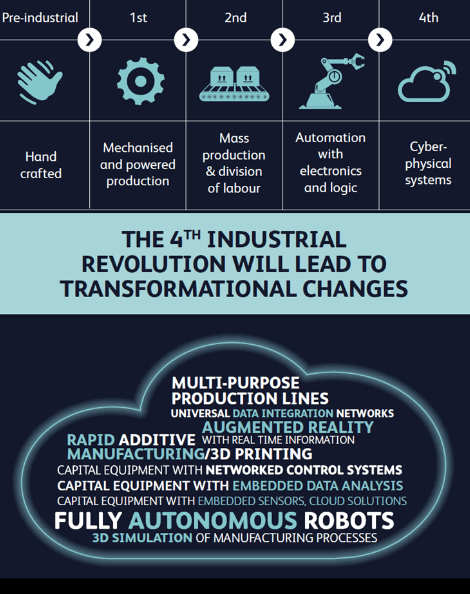

The manufacturing sector is undergoing a profound transformation, driven by emerging technologies and new market dynamics. Dubbed Industry 4.0, the fourth industrial revolution foretells an interconnected, intelligent, and highly automated future for manufacturing. Integrating principles from IT and operational technologies, Industry 4.0 enables real-time data collection, advanced analytics, predictive maintenance, and adaptable automation.

Reducing Costs And Downtime With Industry 4.0

Smart manufacturing powered by technologies such as the Industrial Internet of Things (IIoT), Artificial Intelligence (AI), and collaborative robotics can enhance quality, productivity, and sustainability. A survey by PwC estimates that it is possible to achieve over 30 per cent savings in maintenance costs and a 50 per cent reduction in downtime from utilising data-driven insights and predictive analytics. However, realising these benefits involves significant initial investments and organisational change management:

Securing Supply Chain Resilience

Building supply chain resilience is also crucial, as the pandemic and subsequent war in Ukraine exposed vulnerabilities to global disruptions. Strategies include diversifying the supplier base across regions, improving supply chain visibility through digital tools, and instituting contingency plans based on risk mapping. A robust business continuity plan can also minimise downtime from local disruptions.

Staying Agile In The Face Of Change

As the manufacturing sector continues to evolve, organisations must regularly re-evaluate their long-term plans and priorities: tracking emerging technologies, changing regulations, customer preferences, and conducting scenario analysis will be vital. Investments decisions should balance automation and sustainability goals with desired business agility.

Increasing Market Responsiveness

Adopting lean manufacturing principles and flexible production approaches can also facilitate greater responsiveness to market changes. Small batch manufacturing, modular equipment design, and reconfigurable production lines facilitated by the IIoT allow smooth scaling of output. Equally, cross-training, and upskilling workforce in digital technologies is essential.

Staying Ahead Of Your Competitors

An adaptable organisation that can anticipate and respond to change proactively will be well positioned to unlock the promise of smart manufacturing. The ability to collect data-driven insights and recalibrate strategies accordingly will separate the leaders from their less prepared competitors. Surviving the future of manufacturing necessitates building organisational resilience today through technology, talent, and investments in supply chains.

Hone-All: At The Forefront Of Precision Machining Technology

At Hone-All, we provide expert precision machining services for manufacturers who are ready to embrace the evolving manufacturing landscape but lack the resources, labour, or skills to take this on in-house. With decades of experience supporting manufacturers and a consistent commitment delivering the highest standards for our clients, we are the first choice for outsourcing honing, deep hole boring, and drilling, with all work completed in the UK at our Bedfordshire facility.

For more information, please call us on 01525 370666 or request a quotation for your next project.