Honing is a precision machining process that plays a crucial role in many areas of manufacturing and industry, but there are few applications more demanding than Formula 1.

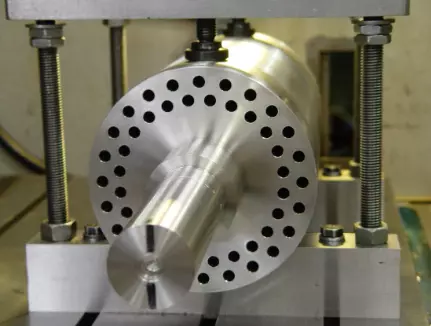

The Anatomy Of Precision: Hydraulic Cylinders And What Sets Them Apart

Hydraulic cylinders are integral components in systems and machines across many industries, providing controlled and reliable power transmission through linear motion. Engineered to exacting standards, they enable extraordinary levels of accuracy and customised performance that are critical for many high-precision applications.

Topics: CNC Honing, Domestic Manufacturing, Hydraulic Systems

The Role of Precision Industrial Rollers in Modern Packaging Solutions

Precision rollers are cylindrical components that are engineered with meticulous accuracy and fine tolerances. These rollers, which are manufactured from high-grade materials, feature precisely designed surfaces and geometries. Offering consistent and controlled movement as well as exceptional reliability, precision rollers play a vital role in the packaging industry which we will explore in this article.

Topics: Packaging Roller, Industrial Rollers, #ukmanufacturing

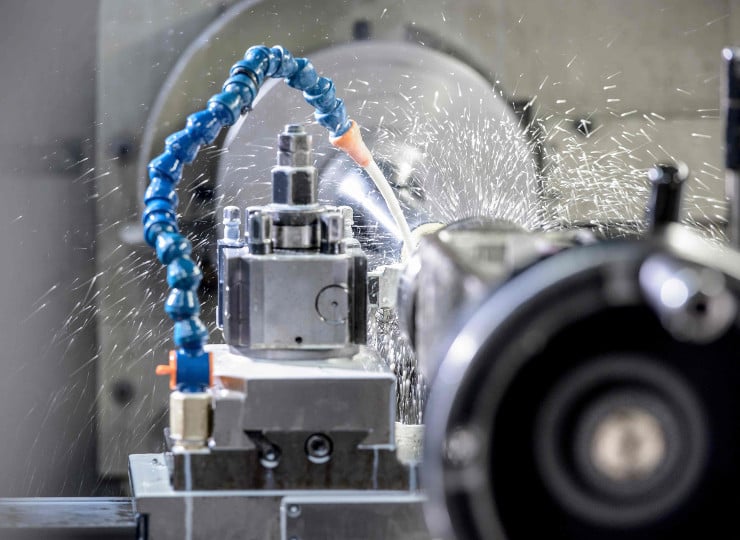

Precision Matters: Why CNC Machining Is Crucial For Medical Equipment

Accuracy in the medical manufacturing sector is non-negotiable as even the slightest error has the potential to alter treatment outcomes or jeopardise patient safety. From initial diagnoses to dosage calculations and surgical procedures, precision directly impacts on the effectiveness of care plans and treatments, ensuring optimum care for each patient.

Topics: Precision Machining, Precision Engineering, CNC Machining

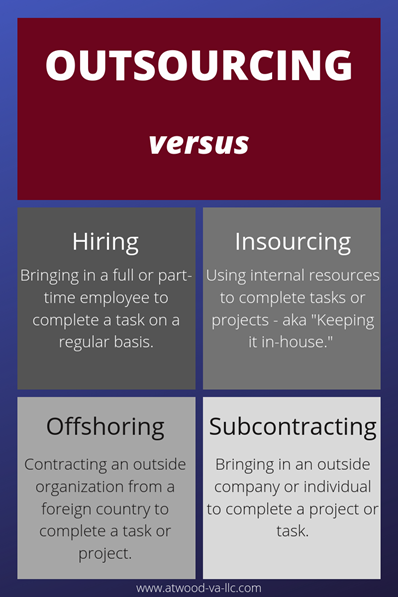

What Is The Difference Between Outsourcing And Subcontracting In Manufacturing?

The UK has a proud history of producing some of the best quality defence equipment in the world, from fighter aircraft to missiles and machine guns. As one of the most dynamic manufacturing industries, which, together with aerospace, accounts for over £12 billion in output, the defence sector is well-positioned to support the UK economy as it rebounds from the slump caused by the global pandemic.

Topics: Aerospace Industry, UK Manufacturing

WHAT YOU SHOULD KNOW BEFORE YOU ASK FOR A CNC GUNDRILLING QUOTE

When the limitations of conventional drilling pose an obstacle to your project, CNC gundrilling provides a cost-effective and reliable way to drill holes with a diameter to depth ratio in excess of 100:1. CNC gundrilling combines Computer Numerical Control (CNC) technology with high-quality, carbide gundrill tools to create holes between 3mm and 28mm in diameter, up to 2,500mm deep.

Topics: CNC Machining Quotes

Questions To Ask Roller Manufacturers For The Best Quality Rollers

Receiving the best quality rollers from a precision roller manufacturing company largely depends on an effective contract review and process planning activity. Having a clear design brief shortens the manufacturing process and reduces the risk of problems occurring with the components. What questions should you ask and what information do you need to provide to be assured of the best result?

Topics: Precision Rollers

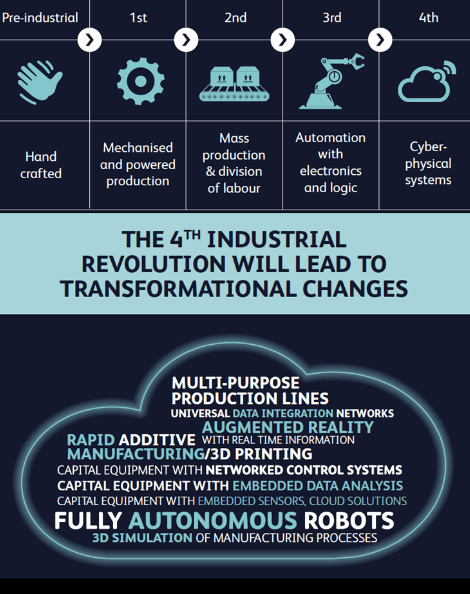

Adapting To The Evolving Manufacturing Landscape: A Look Ahead

The manufacturing sector is undergoing a profound transformation, driven by emerging technologies and new market dynamics. Dubbed Industry 4.0, the fourth industrial revolution foretells an interconnected, intelligent, and highly automated future for manufacturing. Integrating principles from IT and operational technologies, Industry 4.0 enables real-time data collection, advanced analytics, predictive maintenance, and adaptable automation.

Topics: #shoutaboutukmfg, #supportukmfg, #ukmanufacturing

Applications Of Thin-Wall Tubular Components In Modern Food Processing

Thin-wall tubular components play a vital role in modern food processing equipment and operations. With highly skilled expertise, and advanced manufacturing methods, enabling precise dimensions and finishes, these lightweight yet durable components deliver crucial advantages that promote improved hygiene, efficiency, and food safety across the industry.

Topics: Tube Manufacturing, #supportukmfg, #ukmanufacturing

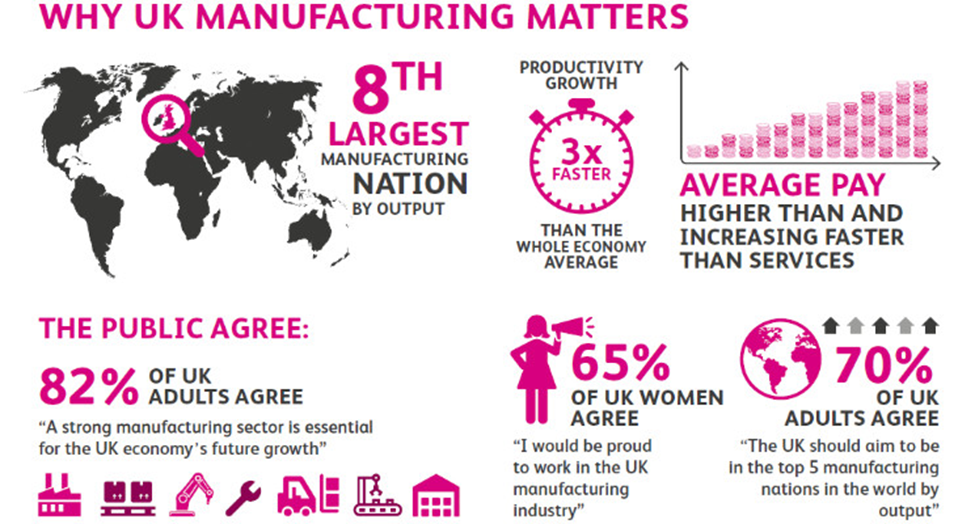

UK Manufacturing's Rise in Global Rankings: What It Means for our Industry

In an inspiring turn of events, the UK's manufacturing sector has made a significant leap in the global rankings, overtaking France to claim the eighth position. This achievement, highlighted in the latest 'Manufacturing – The Facts' report from @MakeUK, is not just a statistic; it represents the resilience, innovation, and continuous growth of our sector.

Topics: UK Manufacturing, #shoutaboutukmfg, #supportukmfg, #ukmanufacturing